how do you accurately layout fret spacing .when hand making your fret bds? iv'e tried fret to fret and end of fret bd. to the next fret and get different results. what do you do?

how do you accurately layout fret spacing .when hand making your fret bds? iv'e tried fret to fret and end of fret bd. to the next fret and get different results. what do you do?

Darrell Tubbs 2007dt special#1 f5 DT mando #2 a5 DT mando #3 a5

Nut to fret, always. You compound error when you go fret to fret.

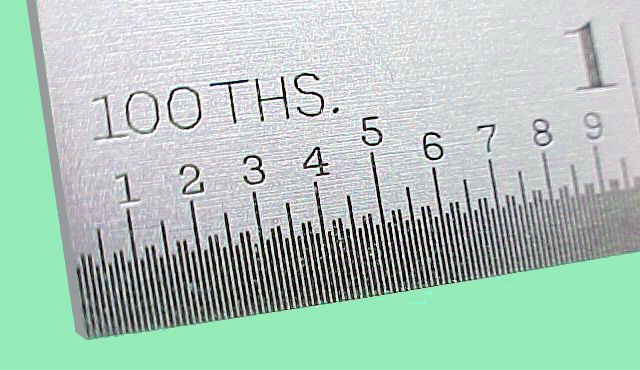

If I can add a bit, I do the measuring with a really plush Starrett edge ruled in 100ths of an inch. I find it as easy as metric, and finer and more accurate. Like Buddy says, nut to fret. When I do a board with a conventional nut, I cut that nut slot a half a saw kerf farther from the first fret so the leading edge of the nut is at and directly above the center of the slot. It's not a huge deal, but it can save hassle later.

If making your fretboards is challenging or you have a very sensitive ear to intonation, try the fret slotting #system from LMI or Stew Mac. The basic idea is that they have an indexed, cnc cut template that allows you to use either a .023" kerf tablesaw blade and a right angle fence or a handsaw and a miter box with very accurate results. It takes about a half hour to setup for the first run and then you can cut a very consistant fretboard in about three minutes. If you make a few extras for your buddies or sell them here or on ebay, you can pay for the entire system the first day you use it.

j.

www.condino.com

Have someone else do it: Steve Smith, Cumberland Acoustic. #

AS LONG AS YOU CAN CALCULATE THE POSITIONS , AND HAVE ACCESS TO THE RIGHT EQUIPMENT , IT IS EASY TO GET THEM WITHIN .0005" ACCURACY USING A MILLING MACHINE AND A DIGITAL READOUT .

THIS CAN BE SET UP WITH A SMALL VERTICAL ENDMILL OR A SLITTING SAW USING

A RIGHT ANGLE ATTATCHMENT . DIAL & CUT !

I would assume (and yes I know the dangers of assumptions) that someone asking this question wants to make their own fretboard, but probably does not want to invest thousands of dollars to make a few.

I have used wfret for layout. You can use it to calculate distance and print a template. I double check the template (my rule only measures to 1/64 inch instead of #1/100 like Paul's) and it has always measured out correctly. Glue the template to your board and off you go.

Wfret can be found on the links page at the Musical Instrument Maker's Forum HERE. Scroll about 40% of the way down the page and look for Jon Whitney's downloadable wfret.

FWIW I purchased my last fretboard preslotted. If you can get an accurately slotted board for a few dollars more than an unslotted board I think it is probably a good way to go.

Bill Snyder

A vernier hight gage can be used to lay out the location of the fret slots. They kind of out dated in industry so are pretty cheap on e-bay or local surplus store.

Dave Schneider

Another way to get an accurate fretboard is to purchase a well made commercial one, and then use that as your master for making future ones by using it as the reference point for an indexing system. The cost is only a few dollars less than one of the lexan templates. About half of the suppliers #that I have dealt with and most of the small production factories all use the same $150 table saw mounted fretting system from LMI. It works great and that is a fair price for a lifetime of accurate fingerboards.

j.

www.condino.com

I use FretCalc and use the nut to fret measurements in MM. It's just easier to be sure I got it right. Also, keep in mind that the calculations give you the distance from the center of a zero fret slot (or the front edge of the nut) to the center of the other frets. Even with the finest blade or pencil, it is easy to end up with the line slightly further away because it is nearly impossible to get dead in the corner of a straigt edge to mark the line. That gets compounded further if you use it as the back edge of the slot (DAMHIKT).

I am a hobbyist on a shoestring budget. A flush cut saw from HF will cut a slot with a kerf thin enough for frets, but requires guides to keep it straight. But if you can afford it, do as James suggests.

"First you master your instrument, then you master the music, then you forget about all that ... and just play"

Charlie "Bird" Parker

I purchased two accurately made preslotted fingerboards 29 slots ebony, I place the uncut board I wish to mark between the two preslotted ones. I use a straight edge aligned with the slotted boards and mark the unslotted one with a mechanical pencil or a marking knife. I then cut the slots either freehand or with a miterbox. I also have used the milling machine method. I usually use the handsaw method because I enjoy the process.

K4 mandcello

Purple “Hannah Montana” octave mandolin

F2 mandolin

Here is a screen shot of the Wfret program and a partial photo of the template.

You can set the Wfret to different scales. If you prefer you can use milimeters.

Bill Snyder

In a drawer someplace I have three 70's factory Martin guitar boards which, when laid side by side, don't begin to match. Some people wonder why they have trouble tuning, and I contend that they're much too trusting. Old Gibson boards were utterly bizarre, though I think the modern world has seen some major improvements. I mentioned this elsewhere recently, hopefully not earlier in this thread, that I just had a very high-end archtop guitar that was flummoxing its owner. I determined pretty quickly that the distance from the nut to the first fret was significantly too long, which of course meant nothing else could possibly work. You'd think a $20K guitar would have the potential to play in tune. Nope.

Bill,

Thanks for the tip on wfret. I had been using FretCalc and then measuring by hand. I assume it will get the measurements right on a Laser Jet (?). I guess very close and consistently wrong is OK also.

"First you master your instrument, then you master the music, then you forget about all that ... and just play"

Charlie "Bird" Parker

Andy print out a template and check it with your rule. If it measures out accurately use the template. If it does not...well just go with what feels right to you.

Bill Snyder

Printing it out should be pretty good, actually, it's the relatives that matter, in the long run. The scale length may be VERY slightly off, but the relative distances on a good laser printer should be quite accurate (as long as you don't do something weird in the print options)

this works for non standard scales.

Dave Schneider

What are we looking at Dave?

Bill Snyder

A vernier hight gage set up to scribe lines on a finger board. It has a scale in thousandths of an inch. You read the scale at the nut end of the board. Add the values from your fret calculator. Set that value on the scale and scribe the line on your board.

Dave Schneider

Yep, that's what I meant by close but consistently wrong would be okay. As long as doubling the distance from the 12th fret wouldn't make the bridge move very far and it is a movable bridge, it would not matter if it were a tiny bit off as long as that was consistent in relative terms.Originally Posted by (buddyellis @ April 24 2008, 07:51)

"First you master your instrument, then you master the music, then you forget about all that ... and just play"

Charlie "Bird" Parker

Bill, do you know how to get wfret to print out landscaped so you don't have to piece together the template?

The photo below gives an example to support what Paul wrote above. The top fretboard is an unused Cumberland Acoustic mandolin fretboard. Cumberland Acoustic has a high reputation for accuracy. The fretboard below came from a 1925 Gibson snakehead that just didn't sound right. While the use of a wide angle lense may have introduced some distortion, I shot this from three feet away, so it's not bad. The 12th fret on the Gibson fretboard was exactly right: halfway between the nut and correct distance for the bridge. The 11th fret is also correct. In person, you can see that actually frets 8-12 are accurate. You can easily see, however, that all of the other frets are off, some by major amounts. On a hunch, I've just discovered something interesting. If I match the 7th fret of the Gibson fretboard with the 7th slot of the Cumberland, the 1st seven frets are close enough to accurate so that no one would know by the ear. If I match the 13th fret of the Gibson with the 13th slot of the Cumberland, all but the top two frets above the 12th are accurate, and the top two are close. But if I set the intonation for the octave, there's no way for the ones that are out to play in tune (short of bending each note). This makes me wonder whether, as some have suggested, there were several templates, and one was off, or if there was one template but the cutter's hand slipped twice, or whether there were several partial templates. All I know is that it should never have happened. It's what I expect (and generally don't get) from extremely cheap mandolins of the period. I seem to recall reading an interview with a Gibson worker who claimed that he had such a good eye that he could cut fretboards without a template, but I could be wrong about that by quite a ways. It could well be. Or maybe they used a slotted miter box, and the slots got wider from the saw rubbing against them, and the cutter took to holding the saw against the left edge as he cut the lower frets. Who knows?

A classic example. If you saw how Gibson cut slots in boards back then, this would be comprehensible. It's funny though - so many people play in boards like this and never know. But they sure spend a lot of time tuning!

Buddy with my printer (an Epson 260R something) I went to printer setup before I printed the template and set the default to print landscape. Of course I need to change it back to potrait now, but that is no big deal.Originally Posted by (buddyellis @ April 25 2008, 14:20)

Bill Snyder

Most of the frets on that fretboard play out of tune, of course--indeed, the ones from the 7th fret down were playing approximately 10 cents flat. The odd thing is that apart from a few jarring notes, I wasn't really registering that notes were flat. However, I felt this general malaise--it just wasn't right, the sparkle wasn't there, despite the otherwise beautiful tone, and I felt no pleasure in it.

Maybe there's something in the human body that sort of resonates (not in the mystical sense, and I'm not proposing some biochemical phenomenon) to the rightness of a scale, whatever the key. Anyway, I'm with Paul on this: if you check that old Gibson fretboard of yours, you may be surprised. I was horrified.

Bookmarks