You need a well lit workbench with good clamping options for starters.

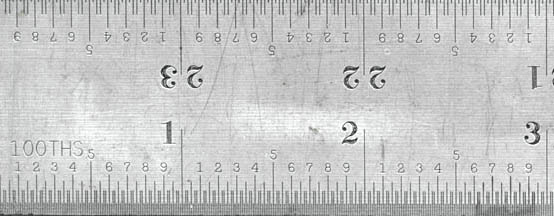

You need to be able to remove a lot of wood quickly for rough shaping. You need to be able to do some fine shaping and some very fine shaping (2 distinctly different activities). Sometimes shaping is scooping. Sometimes shaping is carving. You need to make some cuts that are exactly straight, including some that are to a set depth and have a thin kerf. You need to be able to make wood perfectly flat. You need to be able to measure things precisely. Finishing is another cannaworms I am leaving closed.

For each of the aforementioned operations, you should have a tool that does the job properly. Whether it is an electric tool or hand tool is up to your tastes and budget, though if you are planning to do very much you probably want to have some type of electric saw (table, band or circular) for initial cutting of lumber to rough dimensions.

"First you master your instrument, then you master the music, then you forget about all that ... and just play"

Charlie "Bird" Parker

Reply With Quote

Reply With Quote

Bookmarks